+86-151 9217 7108

+86-151 9217 7108

+86-151 9217 7108

+86-151 9217 7108

High quality steel Die Forging parts with material 40Cr 42CrMo and C70S6

read more

High quality steel Die Forging parts with material 40Cr 42CrMo and C70S6

read more

High quality steel forging parts with material 40Cr 42CrMo and C70S6

read more

OEM high performance steel forging parts at China price.

read more

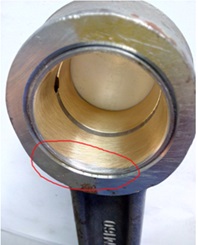

Fracture of copper bush

Possible reasons:

The connecting bar oilhole and the copper bush oilhoe are not in alignment, so the lubrication is not sufficient.

The size of semi-fine boring small hoe is large, leading to small magnitude of interference between the bush and the small hole.

Oil hole malposition: improve the process and equipment, the datum reference adopts variable locating point location, improve the alignment accuracy of two oil holes and the the alignment accuracy has been improved to 0.2mm from the original 0.5mm. The rectification has been completed.

The size of semi-fine boring small hoe is large: the tool has been changed to machine-clamped edging blades from the original welding blades and the diameter dimensional tolerance of the small hoe has been changed to 0.02mm from the original 0.03 mm; the small hole diameter size of every piece will be inspected. The blades will be changed timely according to the size so as to make the size accord with the requirements of the drawing.

Breakage of Connecting Rod bolt

Possible reasons:

Bolt thread size, appearance bumping problem;

The screw tap is not qualified;

Improvement measures

Tighten inspections on bolt cooperation parts, including inspections on macroscopic irregularity of bolts. And a special gauge has been customized to detect the concentricity of the thread and the positioning table.

The brand of the screw tap has been changed. And the screw gauge is used to test the qualifying condition. The threaded hole thread is checked every 8 pieces. The screw tap will be checked and changed timely according to the wearing condition.

online

online 0086-635-4560298

0086-635-4560298 0086-635-4560298

0086-635-4560298 info@techconrod.com

info@techconrod.com +86-151 9217 7108

+86-151 9217 7108