+86-151 9217 7108

+86-151 9217 7108

+86-151 9217 7108

+86-151 9217 7108

High quality steel Die Forging parts with material 40Cr 42CrMo and C70S6

read more

High quality steel Die Forging parts with material 40Cr 42CrMo and C70S6

read more

High quality steel forging parts with material 40Cr 42CrMo and C70S6

read more

OEM high performance steel forging parts at China price.

read more

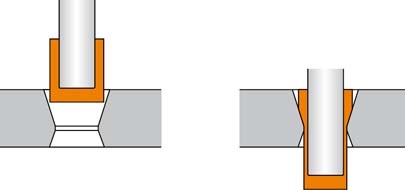

- Reduction

- Extrusion

- Ironing

- Closed Die Forging

- Upsetting/Open Die Forging

- Piercing/Trimming

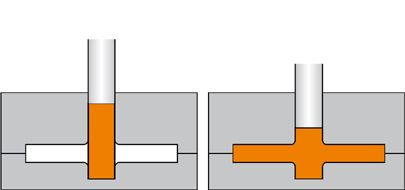

Description of Forging Reduction

Reduction is a forging process in which the workpiece is forced through an opening in the die, fully or in part, involving a reduction in its cross section. Tapering of solid bodies results in a reduction in cross section, whereas hollow bodies, by contrast, are necked.

Reduction

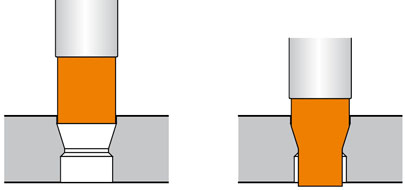

Description of Forging Extrusion

Extrusion is a single or multi-station production process for creating both hollow and solid bodies. The process is distinguished according to the direction of material flow: forward, backwards or lateral. The workpiece is forced through an opening in the die with reduced cross section giving the workpiece its shape.

Full forward extrusion

Backward extrusion

Lateral extrusion

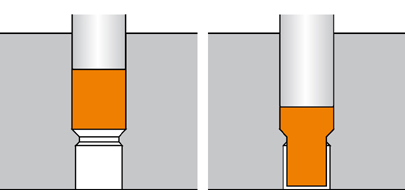

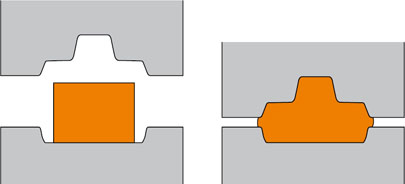

Description of Forging Ironing

Ironing is carried out by pulling the workpiece through an ironing ring with the help of a punch. The wall thickness of the hollow body is reduced in this process.

Ironing

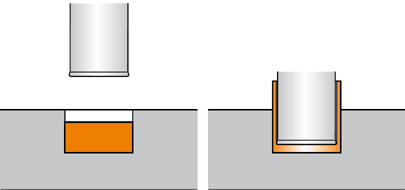

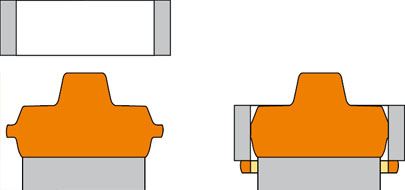

Description of Closed Die Forging

Closed Die Forging is a forging process in which dies move towards each other and covers the workpiece in whole or in part. The heated raw material, which is approximately the shape or size of the final forged part, is placed in the bottom die. The shape of the forging is incorporated in the top or bottom die as a negative image. Coming from above, the impact of the top die on the raw material forms it into the required forged form.

Closed Die Forging

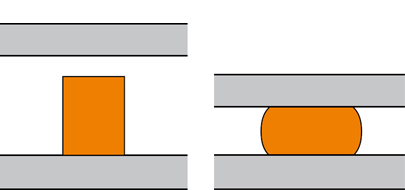

Description of Upsetting and Open Die Forging

Upsetting and Open Die Forging are also forging procedures. Upsetting is principally used for preliminary distribution of the material. In contrast to closed die forging, the workpiece is not completely enclosed during this forging process.

Upsetting

Open Die Forging

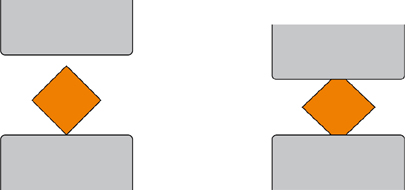

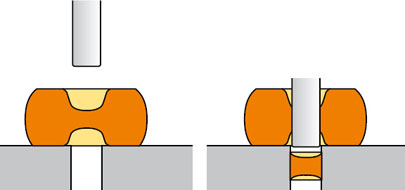

Description of Piercing/Trimming

Piercing is used for incorporating holes and openings into a workpiece, which can have a wide range of shapes and sizes. Trimming involves removing surplus material (flash) from the workpiece.

Piercing

Trimming

online

online 0086-635-4560298

0086-635-4560298 0086-635-4560298

0086-635-4560298 info@techconrod.com

info@techconrod.com +86-151 9217 7108

+86-151 9217 7108