+86-151 9217 7108

+86-151 9217 7108

+86-151 9217 7108

+86-151 9217 7108

High quality steel Die Forging parts with material 40Cr 42CrMo and C70S6

read more

High quality steel Die Forging parts with material 40Cr 42CrMo and C70S6

read more

High quality steel forging parts with material 40Cr 42CrMo and C70S6

read more

OEM high performance steel forging parts at China price.

read more2025-10-08

2024-12-23

2023-01-10

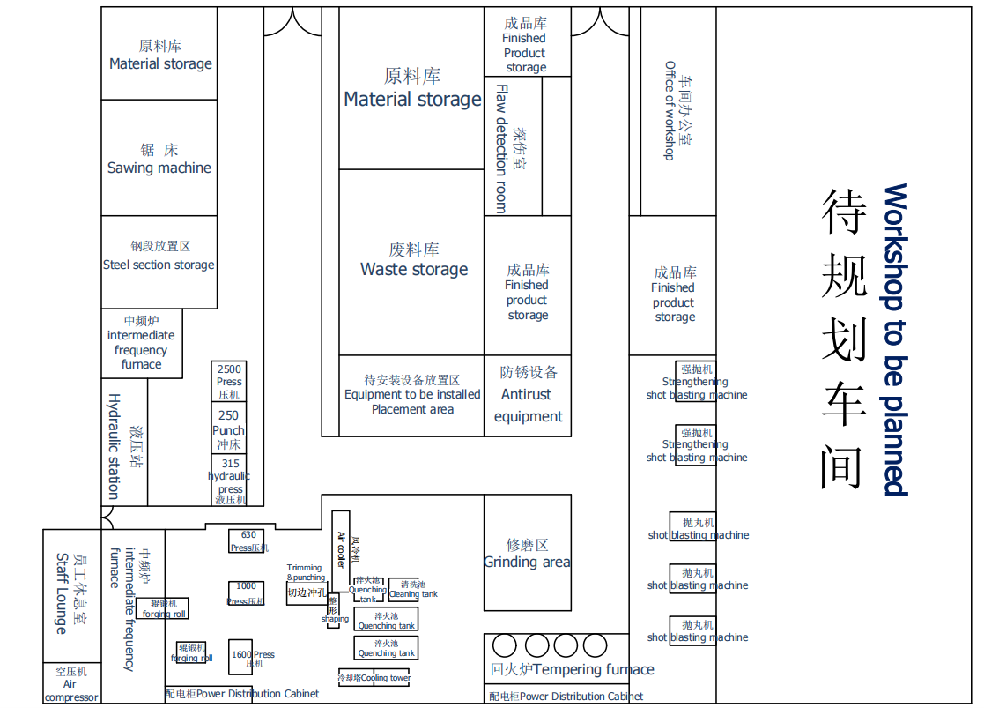

Our new forging workshop is under intensive construction. According to the construction plan, the construction area of the new workshop is about 6500 m2, and the planned investment is 5 million yuan. It is expected that the annual output of forging products will reach 2 million pieces after completion. At that time, the income will be increased by 40 million yuan and 40 jobs will be added.

Forging Workshop Layout 2022 year

Profile of Chiping Yida Machinery Manufacturing Co., Ltd

Chiping Yida Machinery Manufacturing Co., Ltd., established in October 2010, is located in Boping Town Industrial Park, Liaocheng City, Shandong Province. It is a professional forging company and a member of connecting rod Committee of China Forging Association.

The company covers an area of 30000 square meters, the existing staff of more than 80 people, including 16 professional and technical personnel. The company keeps close contact and cooperation with a number of professional forging technical institutions, constantly introduces professional technology to improve product quality, and is equipped with four professional forging production lines, including 2500 tons, 1600 tons, 1000 tons and 630 tons of precision forging high-energy electric presses, with professional testing equipment and perfect testing means.

At present, the company has passed the ISO-TS16949 quality system certification, and has various testing equipment, such as impact testing machine, coordinate measuring machine, spectrograph, video measuring system, hardness tester, tensile testing machine, all kinds of physical and chemical testing equipment, etc., to ensure the mechanical properties and quality requirements of products by precise means. The product range includes construction machinery forgings, steel piston forgings, automobile chassis parts, engine connecting rod forgings, etc., which can also be produced according to customer demand.

Quality

The company has passed ISO 9001:2008 and ISO/TS16949 quality system certification. In 2017, it obtained the latest IATF16949:2016 quality system certification.

Team

We have a united, cooperative and efficient team, all members in their respective posts due diligence, mutual cooperation, to provide customers with professional and fast solutions.

online

online 0086-635-4560298

0086-635-4560298 0086-635-4560298

0086-635-4560298 info@techconrod.com

info@techconrod.com +86-151 9217 7108

+86-151 9217 7108